Learning Objectives

- Understand the differences between ultimate and nominal wind loads on buildings

- Review the calculations of wind pressures using ASCE/SEI 7 standards

Since the release of the 2010 version of ASCE/SEI 7 standard “Minimum Design Loads for Buildings and Other Structures”, designers and contractors put effort to make sure they specify or use the right values of wind speed and wind pressure corresponding to the project’s specified building code and selected design method. ASCE/SEI 7-10 made the jump from using nominal wind speeds intended for the Allowable Stress Design (ASD) method to ultimate wind speeds intended for the Load and Resistance Factor Design (LRFD) method. This change was meant to ensure the compatibility between ASCE 7’s wind loads and seismic loads, where seismic loads have been calculated at the ultimate level for years.

Additionally, with ASCE/SEI 7-10 each Building Risk Category has its own ultimate wind speed map, based on wind events of different recurrence intervals. ASCE/SEI 7-05 used to have one nominal wind speed map, independent of the Building Occupancy Category (the term that was replaced by Building Risk Category in 2010). It is worth noting that ASCE/SEI 7-10 is referenced by the 2012 and 2015 versions of the International Building Code, while ASCE/SEI 7-05 is referenced by the 2009 International Building Code.

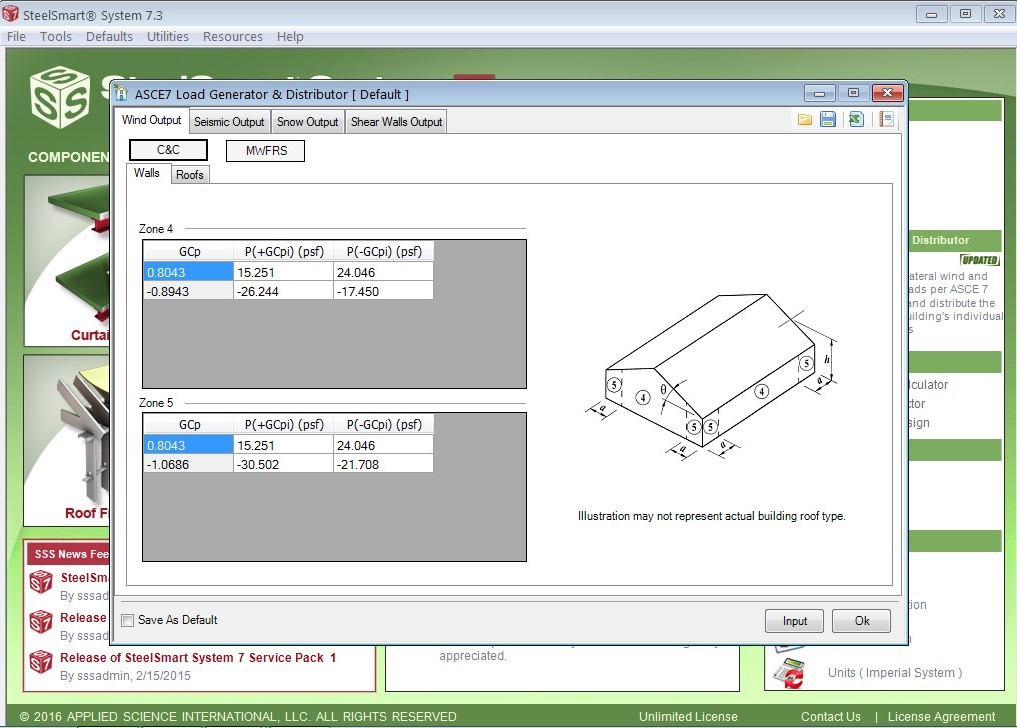

To put things in perspective, let us look at an example to explain the differences between ultimate and nominal wind load calculations. If we calculate the Component and Cladding wind pressure for an exterior wall of a building located in USA Zip Code 32837, we find the following:

Zip code 32837 (assume Risk Category = II, Wall Effective Area = 40 sq. ft., Exposure = C)

| ASCE/SEI 7-10 | ASCE/SEI 7-05 |

| Ultimate wind speed = 137 mph | Nominal wind speed = 105 mph |

| Design wind pressure W = 37.2 psf | Design wind pressure W = 21.9 psf |

| Wind LRFD load combination = 1.0W = 37.2 psf | Wind LRFD load combination = 1.6W = 35.0 psf |

| Wind ASD load combination = 0.6W = 22.3 psf | Wind ASD load combination = 1.0W = 21.9 psf |

Reviewing this example, it can be seen that although ASCE/SEI 7-10 uses higher wind speeds and higher design wind pressures, the use of proper factors in LRFD or ASD load combinations typically yields similar wind pressure requirements when compared to the older ASCE/SEI 7-05 standard. The use of validated software programs to calculate wind pressure requirements helps in making sure the proper code reference and load combination factors are used. The designer, however, is recommended to always do multiple checks on software output.

When the wind design criteria is transferred between designers for the same project– specially between the Engineer of Record and Specialty Engineers – it is recommended that reference ASCE/SEI 7 version and the wind speed basis (ultimate or nominal) are clearly communicated in writing. FDR Engineers makes sure that this information is communicated to other designers in the drawing set and on the cover of the calculation sheets. This simply saves time and effort for FDR’s clients, and ensures the building is safely designed according to the specified building code.

Recent Comments